About PPV/PPA

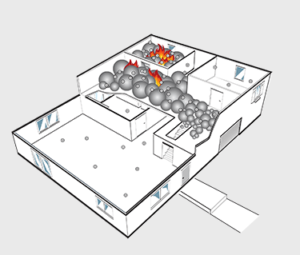

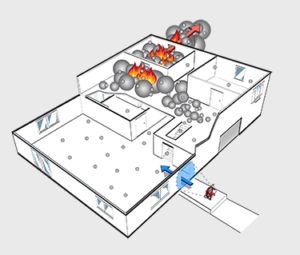

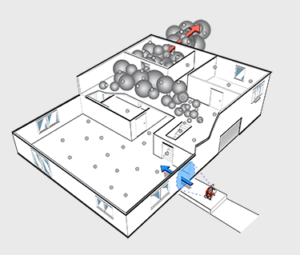

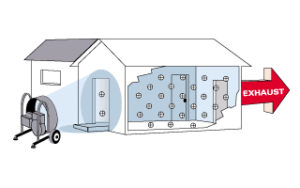

Positive Pressure Ventilation, or PPV as it is commonly known, is a technique within both firefighting and industrial applications that uses air as a tool to control a hostile environment inside an enclosed structure. A variation of this, called Positive Pressure Attack (PPA), is the use of positive pressure ventilation during the attack phase of firefighting specifically. Small electric, gasoline-powered and battery-powered blowers/fans (Tempest Power Blowers) are used to replace a hostile interior environment with fresh, cool ambient air.

The most common blowers / fans range in size from 18″ to 27″ (460mm to 690mm) in diameter and deliver from 7,000 to 24,000 CFM (11,900 m3/hr to 40,600 m3/hr). Positive Pressure Ventilation (PPV) was first developed in the United States in the 1960’s and was used on a limited basis by progressive fire departments. In the early 1990’s, information about the use and applications of PPV became widely available and research was conducted to study the benefits it offered to firefighters. Today, PPV is an accepted firefighting technique and is used by fire departments and fire brigades around the world.

Protecting your personnel from hazardous environments is vital. Effectively ventilating toxic gases and smoke from fires, as well as harmful dust, fumes and other contaminates in industrial applications, will make your work environment safer.

Two ventilation techniques are most effective for achieving this goal: Positive Pressure Ventilation (PPV) and Negative Pressure Ventilation (NPV). PPV has changed firefighting worldwide and is increasingly popular in industrial applications. First adopted in the U.S.A., it has now become a standard technique in Europe and Asia, replacing the use of NPV.

Protecting your personnel from hazardous environments is vital. Effectively ventilating toxic gases and smoke from fires, as well as harmful dust, fumes and other contaminates in industrial applications, will make your work environment safer.

Two ventilation techniques are most effective for achieving this goal: Positive Pressure Ventilation (PPV) and Negative Pressure Ventilation (NPV). PPV has changed firefighting worldwide and is increasingly popular in industrial applications. First adopted in the U.S.A., it has become a standard technique in Europe and Asia, replacing the use of NPV.

Other PPV applications

Removal of Smoke from Ships and Boats

Removal of Smoke from Ships and Boats

Positive Pressure Ventilation is very effective for ventilating compartmentalized structures such as ship holds. Interior spaces can be cleared in a controlled manner by using sequential ventilation techniques.

Commercial/Industrial Decontamination

Commercial/Industrial Decontamination

PPV can be used to ventilate contaminated/toxic environments or dry hazardous spills. Multiple blowers can be used to ventilate large buildings with oversized openings.

Industrial Smoke, Dust and Fume Removal

Industrial Smoke, Dust and Fume Removal

PPV techniques can be used to ventilate dangerous and/or offensive fumes caused by welding, adhesives and coatings. These fumes can be removed with Tempest Smooth Bore Ducting without contaminating adjacent areas.

Aircraft Fires

Aircraft Fires

PPV offers the fastest and most effective method for clearing smoke, heat, and gases from passenger and cargo aircraft. The interior of an aircraft can be ventilated in only 60 to 90 seconds, improving evacuation procedures and allowing rescue personnel faster, safer entry.

Confined Spaces

PPV can ventilate microenvironments such as tanks, pipelines and tunnels by using the blower’s massive air velocity to push out the stagnant air, replacing it with fresh, cool air.